The Calibration of Volumetric Glassware

The accuracy of the volumetric glassware is an important parameter to report a proper quantitative analysis. According to ASTM international standards, there are two types of glassware, according to their accuracy: type A, which is used for high-accuracy works and complies with ASTM E694 standards, and type B, which has twice the tolerance limit of type A glassware and hence lower accuracy.

While standard glassware is made to ensure the highest accuracy for the measured parameters, these apparatuses often deliver inaccurate measurements. According to ISO 4787 standards, this is caused by several factors, such as the temperature of the vessel and liquid, and the cleanliness of the glass surface. Therefore, it is necessary to perform periodic calibration to ensure a precise volumetric measurement of the glassware.

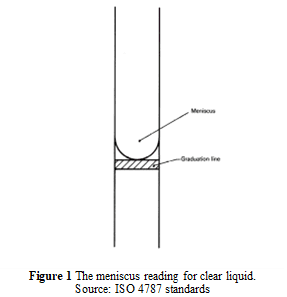

There are important considerations before the calibration is employed. First, it is mandatory to maintain a constant calibration temperature, particularly at 25 ± 2 oC. Furthermore, the lower meniscus level should be used for clear liquid readings (Figure 1), whereas the higher meniscus level is used for colored solution readings.

Volumetric glassware calibration commonly involves these steps.

- Weight a clean and dry beaker glass.

- Deliver deionized water from the calibrated mark of the glassware until it’s empty.

- Repeat the process 3-4 times until a constant mass reading is obtained.

- The volume can then be measured by dividing the mass of deionized water collected with its density at 25oC.